LEFOO Pressure Transmitter Supplier Advantages

A Pressure Transmitter is a device that produces an output electrical signal (ma or microvolt) that varies with the pressure it experiences. When pressure is forced on the crystal chip inside the sensor and the deformed crystal generates a signal. The signal will be transferred by the wire to a display or monitor that can show the signal in value. For example: 4ma=0, 12ma =50 psi, 20ma=100 psi... Pressure sensors are used to inspect the pressure of the gas, fluid, or another medium.

As the pressure sensor manufacturers, LEFOO pressure control designs multiple types of pressure sensor transducers at lower costs and good prices. The pressure sensor transducer includes water level differential pressure sensor, absolute vacuum pressure sensor, smart room temperature pressure sensor, industrial digital hydraulic pressure sensor, piezoresistive pressure sensor, pneumatic pressure sensor with display, OEM pressure sensor, etc.

LEFOO Pressure transducer Manufacturer Advantages

A pressure sensor transducer is a device that consists of a pressure sensor and a signal amplifier, a pressure transducer will translate measured data into a stronger electrical analog signal that can be read and shown on a display by the program controller. A Pressure transmitter is a device that converts a low-class electrical signal from a sensor or transducer to a higher class or a form of data that is available for long distances transmission. Such as 4-20 mA or 485 digital output. These outputs can transmit over long distances. Some transmitters can provide additional data about the device or process measured as part of the communication. The(1-5,1-10)voltage signal is the most stable signal in electrical noisy situations like energy-related industries.

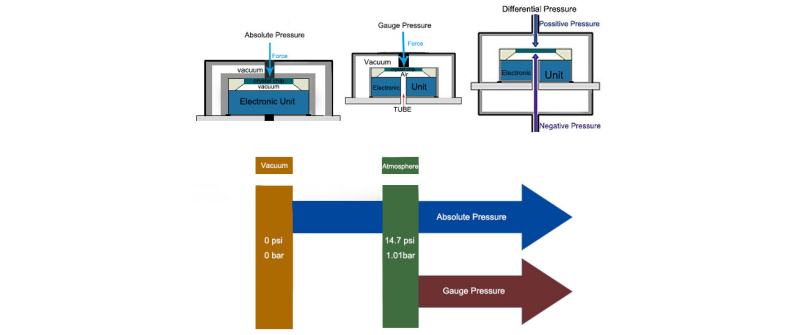

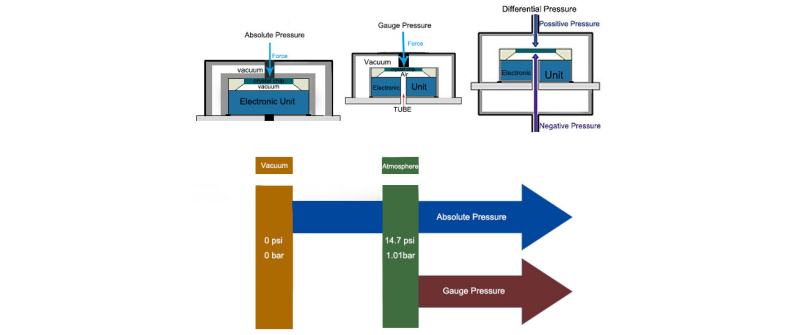

The definitions of absolute pressure, gauge pressure, and differential pressure

Pressure is the force that exists on the surface per unit area. There are three types of pressure measurements: absolute pressure, gauge pressure, and differential pressure. Absolute pressure is referred to the vacuum space (zero atmosphere pressure). In practice, absolute piezoresistive pressure sensors measure the pressure relative to a high vacuum reference sealed behind its sensing diaphragm. Absolute pressure is the sum of gauge pressure(Pg) and atmospheric pressure(Paytm). The acronym for (Kpa: Thousand Pascal) Bar or PSIA (Pounds per Square Inch Absolute. ) Absolute pressure sensor and altimeter are good options for weather monitoring. Usually the standard atmosphere pressure=101.325 pascal=14.7 psi=1.01 bar.

Gauge pressure is actual pressure in a vacuum environment. it is an acronym for PAG (Pascals Gauge) or PSIG (Pounds per Square Inch Gauge) Gauge pressure is measured relative to the environmental atmosphere pressure. Weather conditions and altitude changes directly influence the gauge. Gauge pressure is positive for pressures above atmospheric pressure, and negative for pressures below it. The average atmospheric pressure at sea level is 101.325 kpa.Gauge Pressure =Absolute Pressure-Atmosphere Pressure. Kpa, Bar, PSI are used to describe Gauge pressure value. For a commonly example, in our daily lives, we may pump our car tires from 32 to 40 PSI by the gauge pressure.

Differential pressure is similar to gauge pressure, It is measured based on atmospheric pressure, Differential pressure is composed of high pressure and low pressure, and is usually used to monitoring filters in pipes or tanks when it clogged. Differential pressure is usually an acronym for PAD (Pascals Differential) or PSID (Pounds per Square Inch Differential, Kpa, and Bar). Differential pressure is also used in boiler, high pressure or liquid pressure or level check, and low pressure for an air pressure check. The two pressures will indicate how many liquids are left in the boiler.

The units of pressure are Pascal (Pa, N / m2), pounds / square inch (PSI), atmospheric pressure (atm), and bar. (Bar), an inch of mercury (inch Hg), millimeter of mercury (mm Hg, torr), etc. The PSI and Bar are most commonly used in sensor industries. Liquid Pressure is defined as the strength of a liquid per unit area of its surroundings. For example, pressure (P) is a function of force (F) and area (A). P = F / A, (fluid P gauge=pgh)

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  العربية

العربية