LFH71 is a temperature and humidity transmitter that can be applied in hazardous occasions. The product adopts cast aluminum housing with high protection level, which is suitable for the monitoring of natural gas pipeline network, air supply system of power plant, pharmaceutical factory clean room and other industrial environments with complicated working conditions. The product adopts imported temperature and humidity sensors, with high precision and fast response. The product is divided into intrinsically safe explosion-proof (with display), intrinsically safe dust explosion-proof two models, of which intrinsically safe explosion-proof can work in Zone 0, Zone 1, Zone 2; intrinsically safe dust explosion-proof can work in Zone 20, Zone 21, Zone 22.

Features

* Intrinsically safe, dust explosion-proof certification

* Cast aluminium housing, protection level IP65

* LCD, temperature and humidity dual display

* Imported sensors, high precision, fast response

* Conforms to CE, ROHS standards

Transmitter

| Intrinsically Safe Temperature and Humidity Transmitter with Probe LFH71 | |

| Relative Humidity | |

Sensor | Digital |

| Range | 0%~100%RH |

| Output | 4~20mA(two wire) |

| Accuracy | ±3%@20°C & 20~80%RH |

| Response Time | ≤15s (20°C, Slow flow air) |

Relative Temperature

| Sensor | Digital |

| Range | 0~50°C,-20~60°C etc |

| Output | 4~20mA(two wire) |

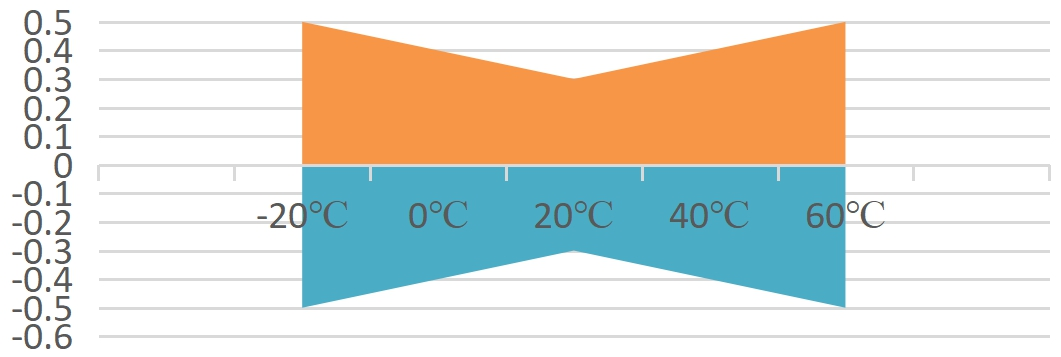

| Accuracy | ±0.3°C@20'c, For other accuracy, refer to the digital sensor temperature accuracy curve below. |

The digital sensor temperature accuracy curve

Intrinsically safe parameters

| Explosion-proof Marking | With display: Ex ia IIC T6/T4 Ga Without display: Ex ia IIC T6/T4 Ga; Ex ia IIIC T200 85°C/T200 135°C Da |

| Explosion-proof Certificate | CE24.2060X |

| Intrinsically Safe Parameters | (RH+、RH-) : Ui : 28VDC; li : 93mA; Pi : 0.65W; Ci : 0.02uF; Li : 0mH (T+、T-) : Ui : 28VDC; li : 93mA; Pi : 0.65W; Ci : 0.02uF; Li : 0mH |

| Environment Temperature | T4 : -40°C~80°C; T6 : -40°C~60°C |

Other parameters

| Power Supply | 9~28VDC |

| Maximum Power | 0.04UV (W) (UV=supply voltage) |

| Output Load | ≤500Ω |

| Display | Intrinsically safe: Optional LCD display (with unit without backlight) Dust intrinsically safe: No display |

| Housing Material | ADC12, stainless steel probe and sintered mesh filter |

| Working Temperature | T4: -40°C~80°C; T6: -40°C~60°C, 5%~95%RH (non-condensing) |

| Protection Class | IP65 |

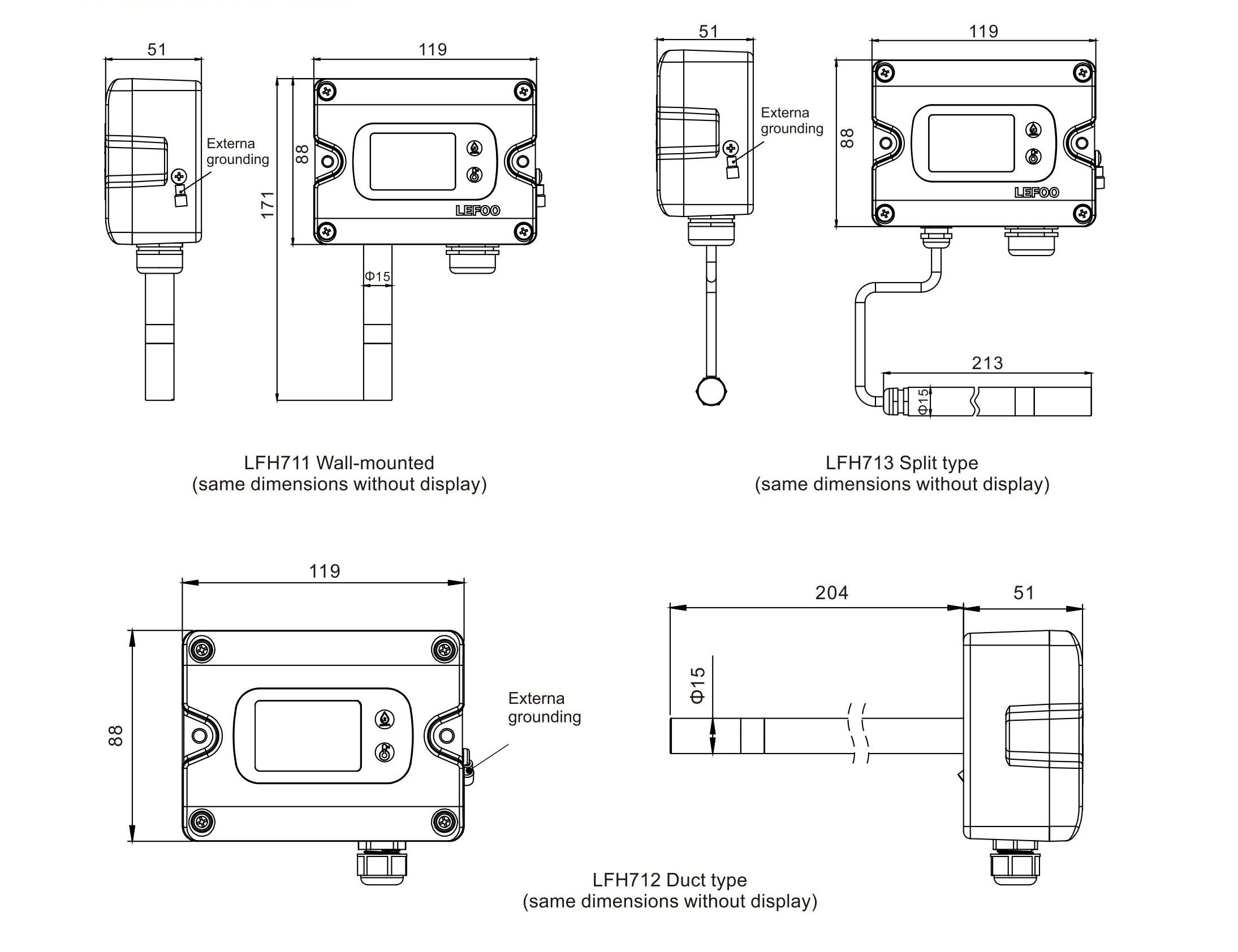

| Weight | ≈666g(Wall-mounted) ≈760g(Duct type) ≈813g(Split type, without accereceries) |

| Certificates | CE,Intrinsically Safe Explosion-proof, Dust Intrinsically Safe Explosion-proof |

WARNING

1.The product housing is made of aluminium alloy, please avoid the risk of ignition during use due to impact or friction.

2. The housing must be reliably grounded during installation.

3.The product display is made of plastic with a potential danger of electrostatic charge. Please avoid friction during use, or wipe

with a wet cloth when cleaning.

4. When the product is used in explosive dust environments, there is a potential danger of electrostatic charge, so it should not

be used in areas affected by charge-generating processes, mechanical friction, separation processes, electronic emission and

pneumatic transmission of dust.

ATTENTION:

ATTENTION:

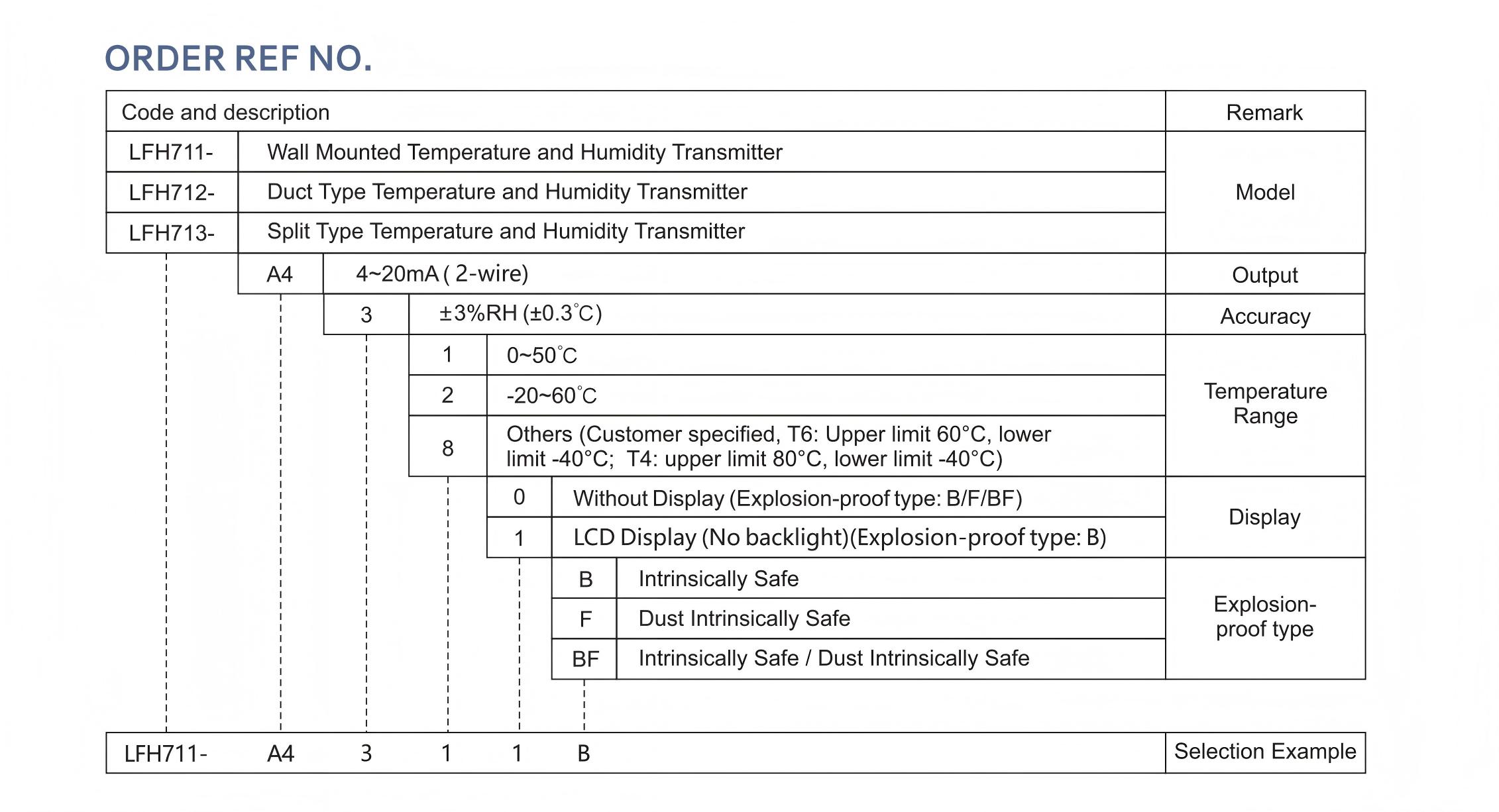

1. Example LFH711-A4A4311B represents wall-mounted type, accuracy of ±3% RH (±0.3'C), humidity output 4-20mA,

Itemperature output 4-20mA, temperature range 0 ~ 50'C, with display;

2. When the temperature range is selected as 8, the temperature range specified by the customer shall not exceed the specified

range,T6: -40°C~60°C; T4: -40°C~80°C;

3. When the display is selected as showing (1), only intrinsically safe type (B) can be selected.

4. Prolonged exposure of the product's sensor probe to high concentrations of chemical gases may cause the sensor's

reading to shift.

Attention:

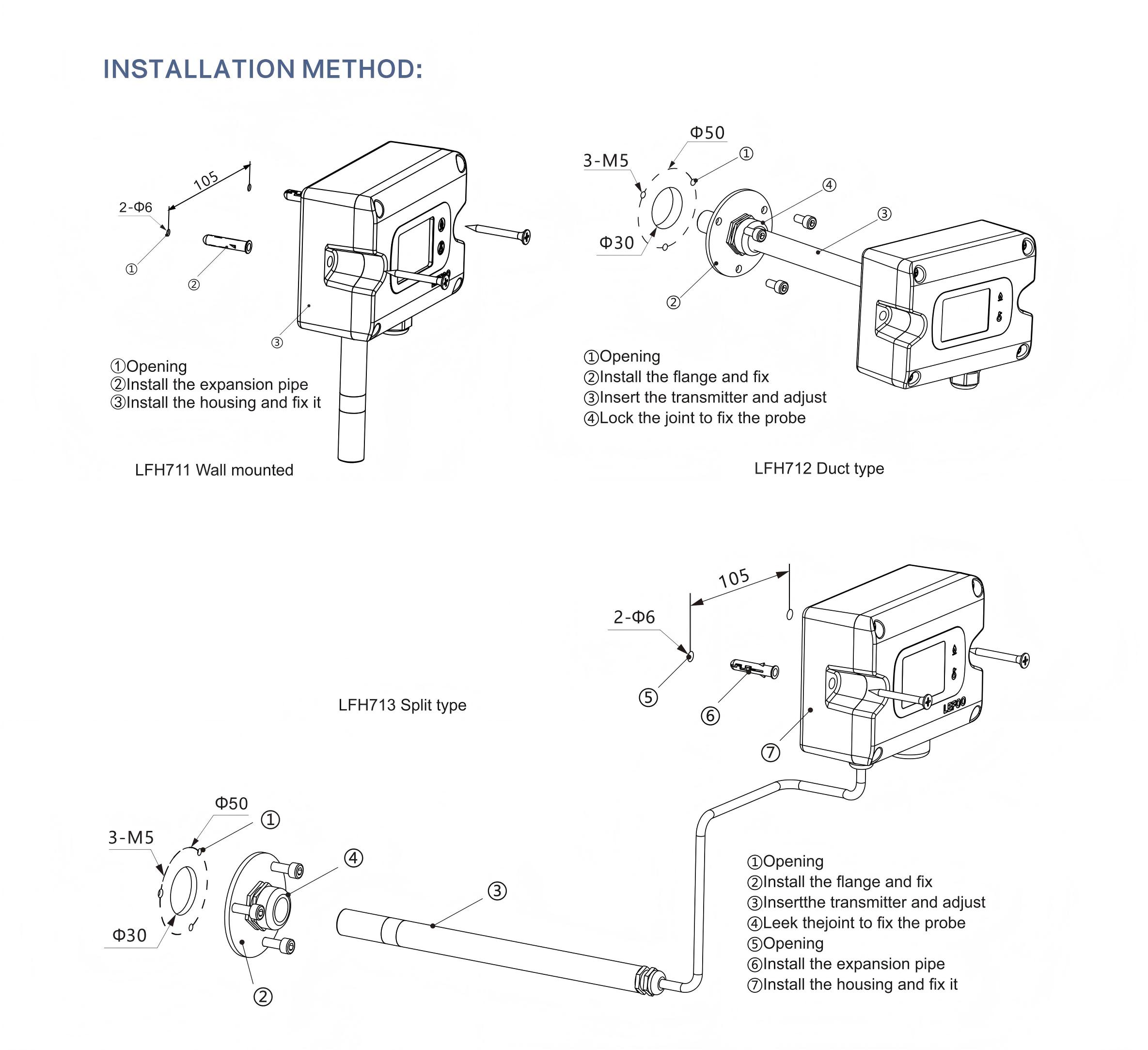

Expansion screws are required if mounted on the wal; machine screws are required if mounted on the iron plate.

* Intrinsically safe, dust explosion-proof certification

* Cast aluminium housing, protection level IP65

* LCD, temperature and humidity dual display

* Imported sensors, high precision, fast response

* Conforms to CE, ROHS standards

Intrinsically safe explosion-proof temperature and humidity transmitters are mainly used in hazardous environments with explosive gases, dust or steam to ensure that the equipment will not cause explosions in normal or faulty conditions. The following are typical application scenarios and industries:

1. Oil and gas industry

- Scenarios:

- Oil and gas drilling platforms (easily leaking explosive gases such as methane and hydrogen sulfide).

- Storage tank areas and pipeline transportation systems in refineries and chemical plants.

- LNG (liquefied natural gas) processing and storage facilities.

- Function: Monitor ambient temperature and humidity to prevent equipment corrosion or abnormal gas concentration.

---

2. Chemical and pharmaceutical industries

- Scenarios:

- Reactors, solvent storage rooms (flammable and explosive chemicals such as ethanol and acetone).

- Dust environments (such as powder medicine production workshops).

- Function: Control production environment parameters to avoid explosions caused by static electricity or high temperature.

---

3. Coal Mines and Underground Operations

- Scenarios:

- Coal mines (methane and coal dust explosion risks).

- Tunnel construction (gas accumulation areas).

- Function: Real-time monitoring of the temperature and humidity of the ventilation system to ensure operational safety.

---

4. Grain and Storage Industry

- Scenarios:

- Granaries, flour mills (dust explosion hazards).

- Ethanol warehouses or alcohol production workshops.

- Function: Prevent dust accumulation or excessive humidity from causing spontaneous combustion.

---

5. Aerospace and Military Industry

- Scenarios:

- Fuel filling areas (aviation kerosene vapor).

- Ammunition storage warehouses.

- Function: Ensure safety monitoring in extreme environments.

---

6. Other Hazardous Environments

- Scenarios:

- Sewage treatment plants (flammable biogas).

- Printing workshops (volatile ink vapor).

- Battery production (volatile gases from lithium battery electrolytes).

---

Why is intrinsic safety explosion-proof necessary?

- Safety standards: Comply with international explosion-proof certifications such as ATEX, IECEx, and UL.

- Technical features:

- Limit circuit energy to ensure that sparks or high temperatures are not sufficient to ignite explosives.

- Usually used in conjunction with isolation barriers (safety barriers) to further reduce risks.

This type of sensor is a key device for safety monitoring in high-risk areas and must be installed and maintained in strict accordance with specifications.

Product Inquiry

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification Systems English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Türkçe

Türkçe  Zulu

Zulu