Pump

RO Pump for household water purifier, soda water machine, sparkling water chiller, and reverse osmosis systems 50GPD.

Pre-Permeate treatment is critical for the lasting of an RO water system to prevent fouling, and too frequent cleanings, and premature failure of the span RO membrane. Here are common RO system issues about Pre-Permeate

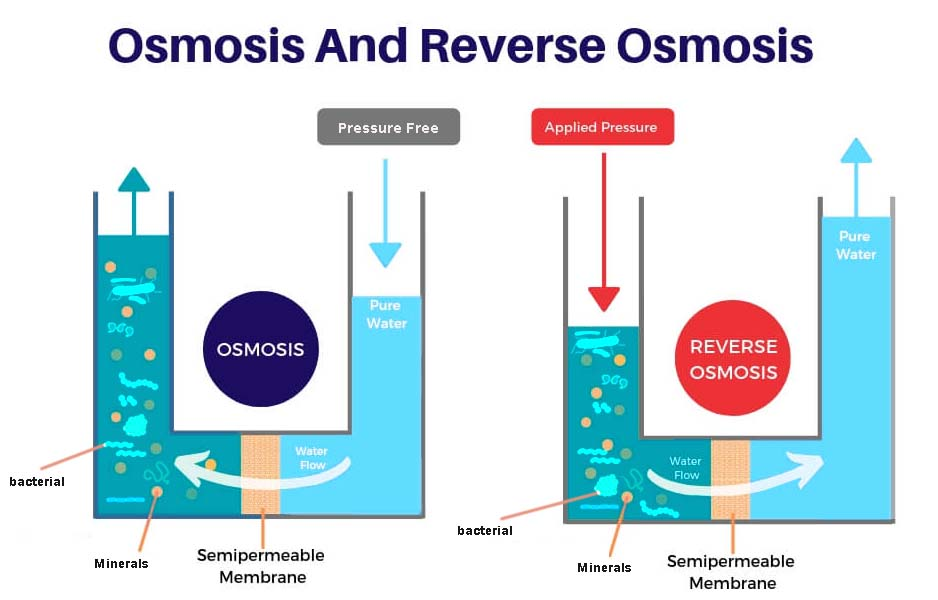

Fouling happens when contaminants accumulate and clog on the membrane surface. There are many contaminants in municipal feed water that are naked to the human eye and harmless for human consumption, but large enough to quickly foul (or clog) an Reverse Osmosis System. Fouling typically exists in the front end of a bare RO system without filters and results in a lower actual RO pressure and a lower permeate flow.

Fouling can be caused by the following:

1. Particulate or colloidal matter (dirt, silt, clay, etc.)

2. Organics (humic/fulvic acids, etc)

3. Microorganisms (bacteria, etc).

4. Breakthrough of filter media upstream of the RO unit. GAC carbon beds and softener beds may develop an under-drain leak and if there is not adequate post-filtration in place the media can foul the RO system.

5. SCALING: An example of a common scale that tends to form on an RO membrane is calcium carbonate (CaCO3).

6. CHEMICAL ATTACK: Oxidizers such as chlorine will 'burn' holes in the membrane pores and can cause irreparable damage.

7. MECHANICAL DAMAGE

'Dry Start' may generate excessive back pressure that can cause permanent membrane damage, you might need a pressure switch to protect the RO system.

1. A Multi-Media Filter (MMF)is used to help prevent fouling of an RO system.

It is important to have a 5-micron cartridge filter placed directly after the MMF unit to prevent the MMF media from damaging downstream pumps and fouling the RO system.

2. Microfiltration (MF) is effective in removing colloidal and bacteria matter and has a pore size of only 0.1-10µm.

3. Antiscalants and scale inhibitors are chemicals that can be added to feed water before an RO unit to help reduce the scaling potential of the feed water.

4. A water softener can be used to help prevent scaling in an RO system by exchanging scale-forming ions with non-scale-forming ions.

5. By adding sodium bisulfite (SBS or SMBS), which is a reducer, to the water stream before an RO at the proper dose you can remove residual chlorine.

6. Granular activated carbon is used for both removing organic constituents and residual disinfectants (such as chlorine and chloramines) from water.

Those Pre-Permeate Solutions need correct designs, maintenance programs, and experienced service support, your RO water system could serve many years of high purity water. Most RO membranes need at least 60 psi pressure to work well, if the water pressure is too low you need to retrofit an RO motor pump.

Parasites, bacteria, Calcium, Fluoride, Lead, Mercury, Phosphate, Chlorine Chloramine, Pesticides, Arsenic, Nitrates, Nickel, virus, Sulfates, Sodium, Detergents, alkali, Barium.

16 Mar 2025

Types of Pump for Water Purifiers and Analysis of Malfunctions01 Mar 2025

Knowledge About Refrigerant Pressure Transducers13 Feb 2025

LEFOO Showcases Innovations at Aquatech Amsterdam 202512 Jun 2024

Unlocking Clean Water: How Booster Pumps Enhance Purification SystemsProduct Inquiry

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Türkçe

Türkçe  Zulu

Zulu